Posted by DeckWise

What’s The Difference Between Air Dried and Kiln Dried Hardwood?

Green wood is no good.

Don’t let your wood drying method lead to a deck building disaster.

Are you getting ready to build a deck, but your lumber is all wet? Well, when wood gets wet it swells and does not allow you to know its true size (this is referred to as “green wood”). Building a deck with “green wood” will result in an uneven deck that may become unstable to walk on.

If you are putting in the time and money to create this new deck wouldn’t you want the best result? Choosing the proper wood drying method will truly change the overall look and longevity of your deck. There are two different methods to properly dry wood. These two methods are known as Air-Dried and Kiln-Dried.

What is Air-Dried?

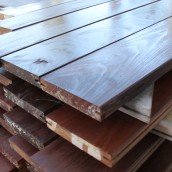

Air drying lumber is the classic method to drying wood and has been around for ages. This process requires the wood to be stacked in layers on a raised foundation in a cool, dry area and separated with stickers (aka thin wood shims).

Positives

- This method results in the wood appearing more natural.

- If completed properly, the wood tends to look more attractive, have a higher quality, and be more workable.

- This is a gentler process on the wood.

Negatives

- If this process is done too quickly, case-hardening and internal checking (aka honeycombing) can occur.

- The air drying method can sometimes leave water and sticker marks.

- Equilibrium moisture content (EMC) can be left unequal. EMC is the balance of wood moisture content reaching the moisture content of the surrounding air. If this is unequal, problems of “green wood” can occur.

- This process can take a longer time to properly complete.

- Typically this wood drying process needs to be reacclimated to the new climate prior to installation.

What is Kiln-Dried?

Kiln drying lumber is also known as “controlled air drying,” which dries the lumber in a controlled atmosphere.

Positives

- This method allows wood to dry quicker and more even, which allows for immediate installation and immediate application of surface and end protectant (such as Ipe Oil™ or Ipe Seal™).

- If completed properly, the wood tends to be straighter with fewer defects, and it is easier to measure accurately.

- This process typically results in less mold development and insect infestation.

- Kiln drying can also reduce the cost of shipping because the wood has less water weight.

Negatives

- Depending on the species of lumber, kiln drying can be more expensive.

- Internal stresses (such as checking, splitting and warping) can occur if dried improperly.

Though these two methods are vastly different, they both provide the builder with advantages and disadvantages. Choosing between the two will ultimately depend on the builder’s preference, budget and project size. Regardless of your choice, We want to leave you with a few tips that will make your deck building more beneficial.

- To insure proper gap spacing use gap spacers (we recommend DeckWise™ Deck Board Spacers).

- Ask your lumber supplier about how to store and handle your lumber purchases properly.

Thanks for this post Wiseguys, wood drying and wood movement is a topic that seems to confuse a lot of people. As builders we tend to forget all the stuff that goes on before we get our lumber. I must caution your assumption that kiln dried wood doesn’t’ need time to acclimate to the build environment. All wood moves. It is an organic, hydroscopic material that is constantly seeking equilibrium with the local environment. Kiln dried lumber actually takes longer to achieve that equilibrium because the lignin is more set and the cell walls more rigid and it won’t absorb much. Air dried lumber isn’t as rigid and will more readily soak up moisture. Regardless, both will absorb and shed water throughout their lifetime and the associated movement must be accounted for in any project.